Working Principle

The raw material enters the crushing chamber from the star valve through the inclined tube through the grading chamber, and is severely impacted by the impact hammer. The pulverized material rises to the classification wheel with the airflow for classification, and the fine powder that meets the fineness requirements is discharged.

Features

This machine integrates mechanical crushing and air classification, and is a new type of combined equipment with compact structure.

This machine has a split mechanism, which divides the grading and crushing parts into two parts, which is convenient for inspection, cleaning and maintenance.

The production capacity is large, the maximum raw material particles can reach about 15mm, and the product particle size can be adjusted arbitrarily within the range of d97=6-150um.

Generally suitable for materials with a Mohs hardness of 3.5. Using special wear-resistant materials, it can be applied to material hardness Mohs 7.

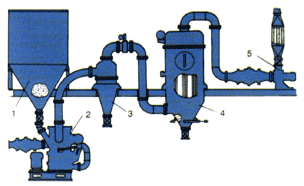

Schematic Diagram of The Mechanical Pulverizer of The JCF System

1. Silo

2. Host

3. Cyclone Separator

4. Bag Catcher

5. High Pressure Fan

Scope of Application

Pesticides, limestone, talc, kaolin, silica, corundum, paraffin, aluminum hydroxide, lactose, cocoa mixture, etc.

The Main Technical Parameters

|

|

JCF300 |

JCF400 |

JCF630 |

JCF1000 |

JCF1250 |

|||||

|

Grading |

Smash |

Grading |

Smash |

Grading |

Smash |

Grading |

Smash |

Grading |

Smash |

|

|

Motor Power(mm) |

3 |

7.5 |

7.5 |

18.5 |

11 |

379(45) |

15 |

75(90) |

30 |

160 |

|

Rotating Speed(max r/min) |

8000 |

7000 |

6000 |

5600 |

4000 |

3550 |

2400 |

2250 |

2000 |

1800 |

|

feeding Amount(Kg/h) |

20~150 |

40-400 |

50-1000 |

400-3000 |

3000-4500 |

|||||

|

Weight(Kg) |

700 |

807 |

2450 |

5330 |

7000 |

|||||

|

Dimensions(mm) |

1190*790*1180 |

1460×780×1707 |

2145×1330×1710 |

3460×1866×2350 |

3700*2300*2630 |

|||||

|

Raw Material Particle Size(max mm) |

3 |

5 |

5mm |

15 |

15 |

|||||

|

Product Particle Size(d97 um) |

5-120 |

6-120 |

10-120 |

8-150 |

9-200 |

|||||